Effective inventory management is crucial for any business, as it helps to optimize stock levels, reduce waste, and improve overall efficiency. One powerful tool for achieving this is a Material Requirements Planning (MRP) system, which can be implemented using an Excel template. In this article, we will explore the concept of MRP, its benefits, and how to use a free MRP Excel template to streamline your inventory management process.

What is Material Requirements Planning (MRP)?

Material Requirements Planning (MRP) is a production planning and inventory control system that helps businesses to manage their inventory levels, track demand, and optimize production. It is a widely used methodology in manufacturing and logistics, which aims to ensure that the right materials are available in the right quantities at the right time.

MRP systems take into account factors such as demand, lead times, and inventory levels to calculate the required quantities of materials and components. This information is then used to generate production schedules, procurement plans, and inventory reports.

Benefits of Using an MRP System

Implementing an MRP system can bring numerous benefits to a business, including:

- Improved inventory management: MRP helps to optimize inventory levels, reducing the risk of stockouts and overstocking.

- Increased efficiency: By automating production planning and inventory management, businesses can save time and reduce errors.

- Enhanced forecasting: MRP systems can help to improve demand forecasting, enabling businesses to respond to changes in demand more effectively.

- Better supplier management: MRP systems can help to optimize procurement plans, ensuring that materials are ordered in the right quantities and at the right time.

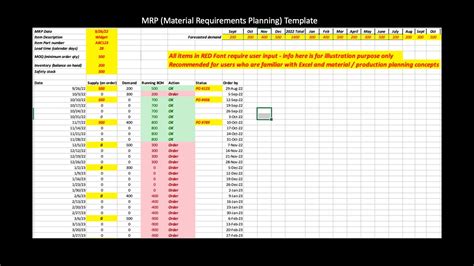

Free MRP Excel Template Download

To help businesses implement an MRP system, we are providing a free MRP Excel template that can be downloaded and used immediately. This template is designed to be user-friendly and flexible, allowing businesses to customize it to meet their specific needs.

How to Use the MRP Excel Template

Using the MRP Excel template is straightforward. Here are the steps to follow:

- Download the template: Click on the link to download the free MRP Excel template.

- Enter your data: Enter your business data, including inventory levels, demand, lead times, and supplier information.

- Configure the template: Configure the template to meet your specific needs, including setting up the bill of materials, production schedules, and inventory reports.

- Run the MRP calculation: Run the MRP calculation to generate the required quantities of materials and components.

- Review and adjust: Review the results and adjust the template as needed to optimize your inventory management process.

Key Features of the MRP Excel Template

The free MRP Excel template includes the following key features:

- Bill of Materials (BOM): A table that lists the materials and components required for each product.

- Production Schedule: A table that shows the production schedule for each product.

- Inventory Report: A table that shows the current inventory levels for each material and component.

- Supplier Information: A table that lists the suppliers for each material and component.

- MRP Calculation: A formula that calculates the required quantities of materials and components based on demand, lead times, and inventory levels.

Example of How to Use the MRP Excel Template

Let's say you are a manufacturer of bicycles, and you want to use the MRP Excel template to manage your inventory of wheels. Here's an example of how you might use the template:

- Enter your data: Enter the inventory levels, demand, lead times, and supplier information for wheels.

- Configure the template: Set up the bill of materials, production schedule, and inventory report for wheels.

- Run the MRP calculation: Run the MRP calculation to determine the required quantity of wheels.

- Review and adjust: Review the results and adjust the template as needed to optimize your inventory management process.

Tips for Implementing an MRP System

Implementing an MRP system can be a complex process, but here are some tips to help you get started:

- Start small: Begin by implementing an MRP system for a small portion of your business, such as a single product or department.

- Use a phased approach: Implement the MRP system in phases, starting with the most critical components and working your way up.

- Train your staff: Provide training for your staff on how to use the MRP system and interpret the results.

- Monitor and adjust: Monitor the performance of the MRP system and adjust as needed to optimize your inventory management process.

Gallery of MRP Excel Template Screenshots

FAQs

What is Material Requirements Planning (MRP)?

+Material Requirements Planning (MRP) is a production planning and inventory control system that helps businesses to manage their inventory levels, track demand, and optimize production.

What are the benefits of using an MRP system?

+The benefits of using an MRP system include improved inventory management, increased efficiency, enhanced forecasting, and better supplier management.

How do I implement an MRP system?

+Implementing an MRP system can be a complex process, but starting small, using a phased approach, training your staff, and monitoring and adjusting the system can help to ensure success.

By using a free MRP Excel template, businesses can streamline their inventory management process, reduce waste, and improve overall efficiency. We hope this article has provided you with a comprehensive understanding of MRP systems and how to use them to optimize your inventory management process.