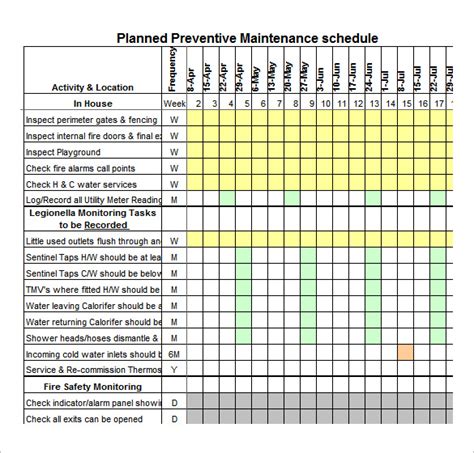

Preventive maintenance is a crucial aspect of maintaining equipment and machinery, ensuring they run smoothly, efficiently, and effectively. By scheduling regular maintenance, organizations can prevent unexpected breakdowns, reduce downtime, and extend the lifespan of their assets. In this article, we will discuss five essential preventive maintenance schedules that can be created and managed using Excel.

Regular maintenance is vital for industries such as manufacturing, construction, and transportation, where equipment failure can result in significant losses. A well-planned preventive maintenance schedule helps organizations stay on top of maintenance tasks, ensuring that their equipment is always in good working condition. By using Excel to create and manage these schedules, organizations can streamline their maintenance processes, reduce errors, and improve overall efficiency.

Benefits of Preventive Maintenance Schedules in Excel

Creating preventive maintenance schedules in Excel offers numerous benefits, including:

- Improved organization and planning

- Enhanced visibility and tracking of maintenance tasks

- Reduced errors and missed maintenance deadlines

- Increased efficiency and productivity

- Better decision-making through data analysis

1. Equipment Maintenance Schedule

An equipment maintenance schedule is a critical component of any preventive maintenance program. This schedule outlines the maintenance tasks required for each piece of equipment, including the frequency and duration of each task.

To create an equipment maintenance schedule in Excel, follow these steps:

- List all equipment in a table, including the equipment name, type, and location.

- Identify the maintenance tasks required for each piece of equipment, including the frequency and duration of each task.

- Create a schedule table with columns for the equipment name, maintenance task, frequency, and due date.

- Use formulas and conditional formatting to track and highlight upcoming maintenance deadlines.

2. Vehicle Maintenance Schedule

A vehicle maintenance schedule is essential for organizations with a fleet of vehicles. This schedule ensures that all vehicles are properly maintained, reducing the risk of breakdowns and accidents.

To create a vehicle maintenance schedule in Excel, follow these steps:

- List all vehicles in a table, including the vehicle make, model, and license plate number.

- Identify the maintenance tasks required for each vehicle, including the frequency and duration of each task.

- Create a schedule table with columns for the vehicle make, maintenance task, frequency, and due date.

- Use formulas and conditional formatting to track and highlight upcoming maintenance deadlines.

3. HVAC Maintenance Schedule

A heating, ventilation, and air conditioning (HVAC) maintenance schedule is crucial for maintaining a comfortable and healthy indoor environment. This schedule ensures that all HVAC systems are properly maintained, reducing the risk of system failures and energy waste.

To create an HVAC maintenance schedule in Excel, follow these steps:

- List all HVAC systems in a table, including the system type and location.

- Identify the maintenance tasks required for each HVAC system, including the frequency and duration of each task.

- Create a schedule table with columns for the system type, maintenance task, frequency, and due date.

- Use formulas and conditional formatting to track and highlight upcoming maintenance deadlines.

4. Plumbing Maintenance Schedule

A plumbing maintenance schedule is essential for maintaining a safe and healthy water supply. This schedule ensures that all plumbing systems are properly maintained, reducing the risk of leaks, clogs, and waterborne diseases.

To create a plumbing maintenance schedule in Excel, follow these steps:

- List all plumbing systems in a table, including the system type and location.

- Identify the maintenance tasks required for each plumbing system, including the frequency and duration of each task.

- Create a schedule table with columns for the system type, maintenance task, frequency, and due date.

- Use formulas and conditional formatting to track and highlight upcoming maintenance deadlines.

5. Electrical Maintenance Schedule

An electrical maintenance schedule is crucial for maintaining a safe and reliable electrical system. This schedule ensures that all electrical systems are properly maintained, reducing the risk of electrical shocks, fires, and equipment damage.

To create an electrical maintenance schedule in Excel, follow these steps:

- List all electrical systems in a table, including the system type and location.

- Identify the maintenance tasks required for each electrical system, including the frequency and duration of each task.

- Create a schedule table with columns for the system type, maintenance task, frequency, and due date.

- Use formulas and conditional formatting to track and highlight upcoming maintenance deadlines.

By creating and managing preventive maintenance schedules in Excel, organizations can ensure that their equipment and systems are properly maintained, reducing the risk of breakdowns, accidents, and costly repairs. By following the steps outlined in this article, organizations can create effective preventive maintenance schedules that improve their overall efficiency, productivity, and bottom line.

We hope this article has been informative and helpful. If you have any questions or comments, please feel free to share them with us.