Equipment failure can have a significant impact on any organization, resulting in costly repairs, downtime, and lost productivity. To minimize the risk of equipment failure, it's essential to have a proactive maintenance strategy in place. One effective way to achieve this is by using an Excel template to track and manage equipment maintenance.

In this article, we'll explore five ways to prevent equipment failure using an Excel template, along with some practical examples and tips to get you started.

Regular Maintenance Scheduling

Regular maintenance is critical to preventing equipment failure. By scheduling regular maintenance tasks, you can identify and address potential issues before they become major problems. An Excel template can help you create a maintenance schedule that's tailored to your equipment's specific needs.

For example, you can create a template with the following columns:

- Equipment ID

- Maintenance Task

- Frequency (e.g., daily, weekly, monthly)

- Due Date

- Completed Date

- Notes

This template allows you to schedule maintenance tasks, track completion dates, and add notes for future reference. You can also use formulas to calculate the next due date based on the frequency and completed date.

Condition-Based Maintenance

Condition-based maintenance involves monitoring equipment conditions to determine when maintenance is required. This approach can help you identify potential issues before they lead to equipment failure. An Excel template can help you track equipment conditions and schedule maintenance accordingly.

For example, you can create a template with the following columns:

- Equipment ID

- Condition Parameter (e.g., temperature, vibration, pressure)

- Threshold Value

- Current Reading

- Action Required (e.g., maintenance, repair, replacement)

- Notes

This template allows you to track equipment conditions, set threshold values, and schedule maintenance when conditions exceed those thresholds. You can also use formulas to calculate the difference between the current reading and threshold value.

Predictive Maintenance

Predictive maintenance involves using data and analytics to predict when equipment is likely to fail. This approach can help you schedule maintenance before equipment failure occurs. An Excel template can help you analyze data and predict equipment failure.

For example, you can create a template with the following columns:

- Equipment ID

- Maintenance History (e.g., dates, tasks, results)

- Failure Patterns (e.g., frequency, severity)

- Predicted Failure Date

- Action Required (e.g., maintenance, repair, replacement)

- Notes

This template allows you to analyze maintenance history and failure patterns to predict when equipment is likely to fail. You can also use formulas to calculate the predicted failure date based on historical data.

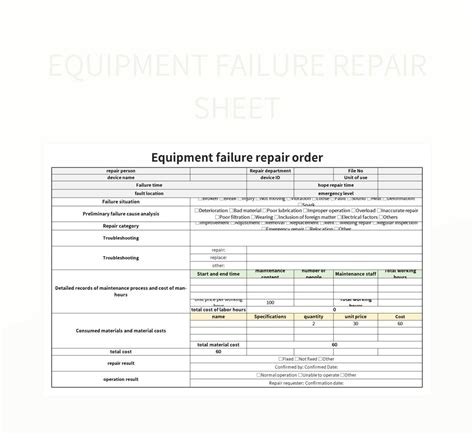

Root Cause Analysis

Root cause analysis involves identifying the underlying causes of equipment failure. This approach can help you address the root cause of equipment failure rather than just the symptoms. An Excel template can help you conduct root cause analysis.

For example, you can create a template with the following columns:

- Equipment ID

- Failure Date

- Failure Mode (e.g., mechanical, electrical, software)

- Root Cause (e.g., design flaw, operator error, maintenance neglect)

- Action Required (e.g., maintenance, repair, replacement)

- Notes

This template allows you to identify the root cause of equipment failure and schedule actions to address that root cause. You can also use formulas to calculate the frequency of each root cause.

Total Productive Maintenance

Total productive maintenance (TPM) involves involving all employees in maintenance activities to improve equipment reliability. This approach can help you identify potential issues before they lead to equipment failure. An Excel template can help you track TPM activities and schedule maintenance accordingly.

For example, you can create a template with the following columns:

- Equipment ID

- TPM Task (e.g., cleaning, lubricating, inspecting)

- Frequency (e.g., daily, weekly, monthly)

- Due Date

- Completed Date

- Notes

This template allows you to schedule TPM tasks, track completion dates, and add notes for future reference. You can also use formulas to calculate the next due date based on the frequency and completed date.

Gallery of Equipment Maintenance Templates

Frequently Asked Questions

What is the purpose of an equipment maintenance template?

+An equipment maintenance template is used to track and manage equipment maintenance activities, including scheduling, condition monitoring, and predictive maintenance.

How can I create an equipment maintenance template in Excel?

+You can create an equipment maintenance template in Excel by setting up columns for equipment ID, maintenance task, frequency, due date, and completed date. You can also use formulas to calculate the next due date based on the frequency and completed date.

What are the benefits of using an equipment maintenance template?

+The benefits of using an equipment maintenance template include improved equipment reliability, reduced downtime, and increased productivity. It also helps to identify potential issues before they lead to equipment failure.

By using an Excel template to track and manage equipment maintenance, you can reduce the risk of equipment failure and improve overall equipment reliability. Remember to schedule regular maintenance, track equipment conditions, and conduct root cause analysis to identify and address potential issues. With the right template and a proactive maintenance strategy, you can keep your equipment running smoothly and minimize downtime.